In our last blogs we get to know about, what is 3D printing, the steps involved in 3D printing, and what is an STL file, we learn about the different types of 3D printers, we read the history of our 3D printers, know about different types of file formats that were used for our 3D printers, and learn what is SLA 3D printers.

Now in this blog, we are going to know about DLP 3D printers.

So, let’s get deep down into it…

Different 3D printers

There are various types of 3D printers available in the market, and which printer you have to use has to be decided by you according to your work need. Here we will discuss all the various 3D printers available, and try to present you with a guide map, that will help you better understating the types of printers.

DLP [Digital Light Processing] Printer

A Digital Light Processing (DLP) 3D printer is a type of additive manufacturing technology that uses a Digital Micromirror Device (DMD) or a similar light projection system to create three-dimensional objects layer by layer. DLP technology is similar to Stereolithography (SLA) in that both methods utilize photopolymerization to solidify liquid resin into a solid object. However, DLP employs a different approach to achieve this process.

Here’s how a DLP 3D printer works:

- Preparation: Similar to other 3D printing methods, the process begins with a 3D model designed using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers using slicing software.

- Resin Tank: The DLP printer has a resin tank that contains liquid photopolymer resin. This resin is sensitive to a specific wavelength of light, usually ultraviolet (UV) light).

- Digital Micromirror Device (DMD): The core component of a DLP printer is the Digital Micromirror Device (DMD). This is an array of micromirrors, each representing a pixel on the final object. The mirrors can tilt to either reflect light (on) or not reflect light (off).

- Layer-by-Layer Build: The DMD reflects UV light in a precise pattern according to the cross-section of the sliced model for a given layer. The UV light is focused onto the liquid resin in the tank and the areas where light is projected to undergo photopolymerization, causing the resin to solidify and form the current layer.

- Platform Movement: As each layer is cured, the build platform moves slightly downward (or the resin tank moves upward), creating a gap between the cured layer and the liquid resin. The process continues, layer by layer until the entire object is complete.

- Curing and Solidification: The UV light projected by the DMD causes the resin to cure and solidify. After each layer is completed, the object remains attached to the build platform.

- Post-Processing: Once the printing process is finished, the object is carefully removed from the build platform. Depending on the printer and resin, post-processing may involve cleaning the object to remove excess resin and, in some cases, additional curing under UV light to ensure optimal material properties.

Advantages of DLP 3D Printing:

- Faster Printing: DLP printers can often cure entire layers at once, making them faster than some other layer-by-layer technologies.

- High Resolution: DLP printers can achieve high-resolution prints with fine details and smooth surfaces.

- Consistency: The use of a digital micromirror device ensures uniform and accurate light projection.

Limitations of DLP 3D Printing:

- Limited Build Volume: The build volume of DLP printers may be limited compared to other technologies.

- Post-Processing: Similar to SLA, DLP prints may require post-processing to remove excess resin and achieve desired mechanical properties.

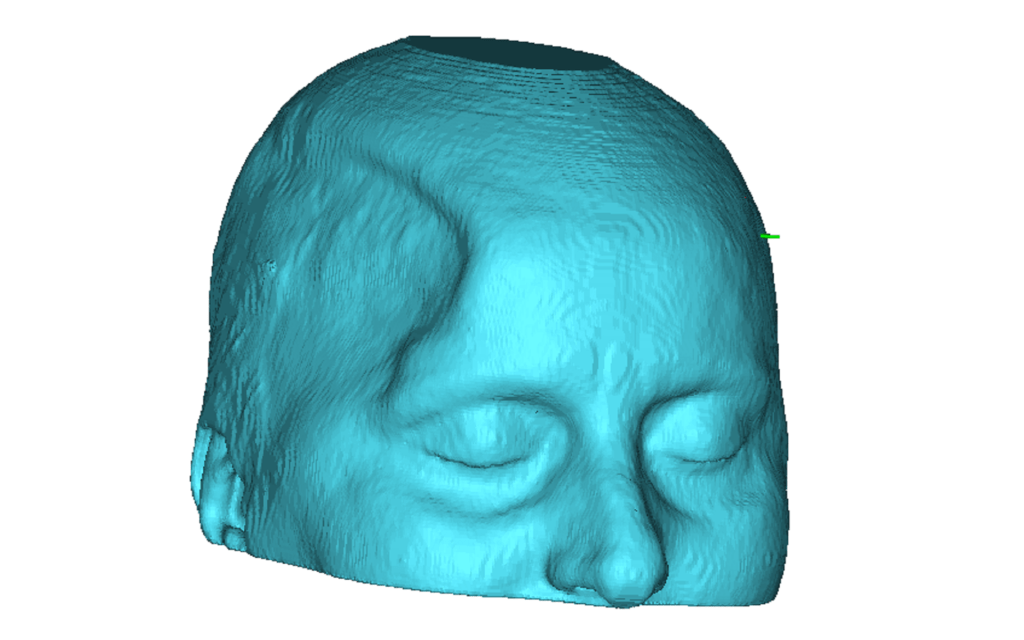

DLP 3D printing finds applications in various industries, including rapid prototyping, jewelry making, dental and medical applications, and creating detailed miniatures or figurines.

The Material Used in DLP 3D Printer

The type of materials [resins] which were used in DLP 3D printers are the same as SLA 3D printers. If you want to know about them go to our previous blog on SLA 3D printing you will get your answer.

Thank you, for being with us till here, now I think you understand the DLP 3D printer.

In the next blog, we are going to know about the difference between the SLA v/s DLP 3D printers.

So, till then keep being awesome and keep learning, We will meet again in our next blog.