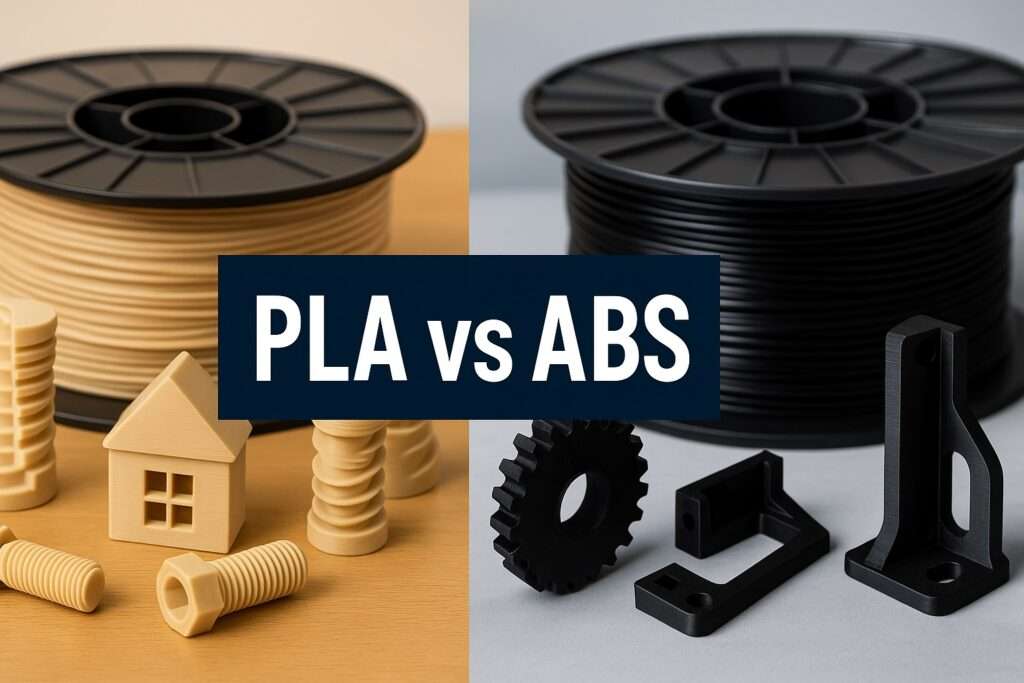

PLA vs ABS Materials in 3D Printing

Welcome to our blog!

If you’re new here, we’ve already covered a range of exciting and essential topics in the world of 3D printing. In our previous posts, we explored the fundamentals of 3D printing, the step-by-step printing process, and the importance of STL files. We also discussed the history and evolution of 3D printing technology, different types of printers, and commonly used file formats.

Additionally, we dove into various 3D printing techniques, including SLA, DLP, SLS, and FDM, and provided a detailed comparison between SLA and DLP to help you understand their unique characteristics.

If you haven’t explored these topics yet, we highly recommend checking out our earlier posts for a strong foundation. You can find them all in our 3D Printing Blog Archive.

As part of this ongoing series, today’s post will focus on one of the most frequently asked comparisons in 3D printing — the key differences between two popular materials: PLA and ABS.

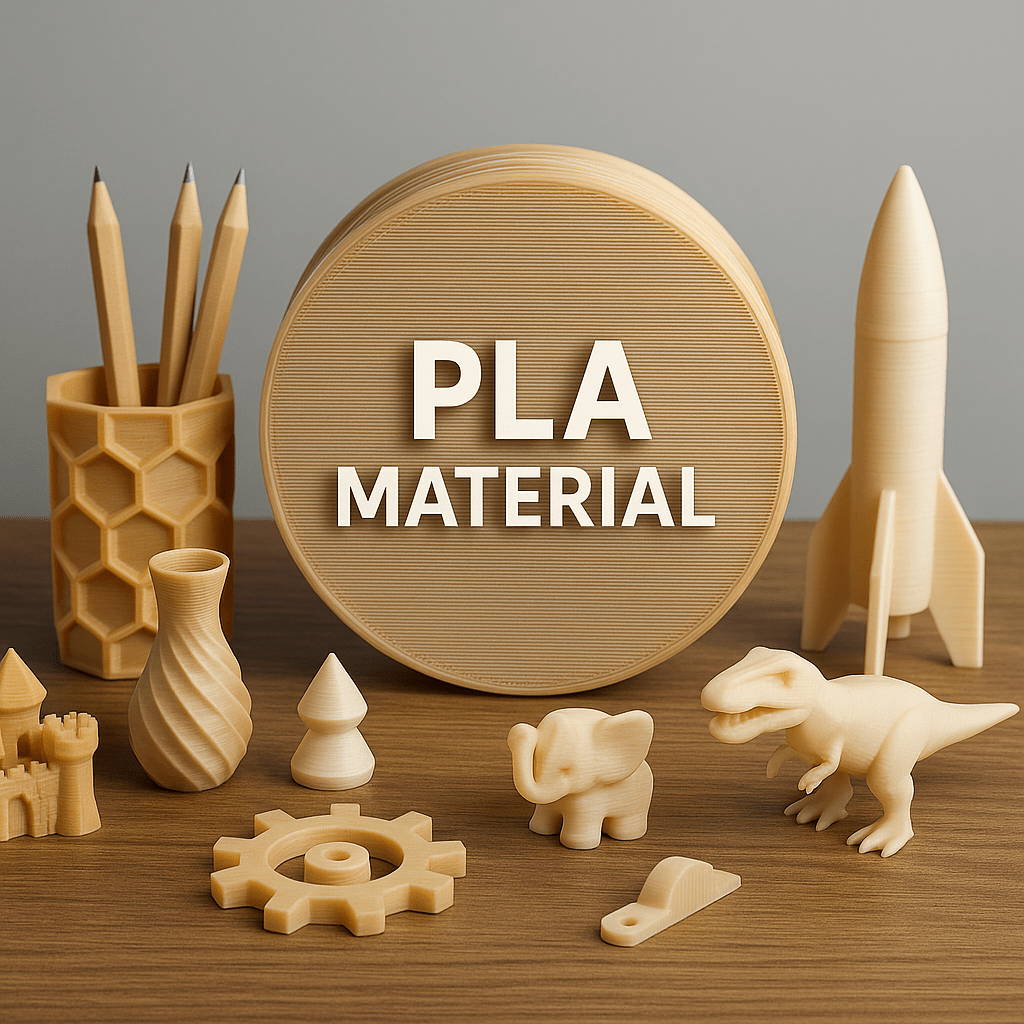

About PLA Material

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources like cornstarch or sugarcane. PLA is popular in 3D printing due to its sustainability, ease of use, and the fact that it is considered environmentally friendly compared to many other plastics.

Key Characteristics of PLA:

- Biodegradability: PLA is compostable under specific conditions, making it an eco-friendly option. However, it does require industrial composting conditions to break down fully.

- Ease of Printing: PLA is known for its low warping, easy adhesion to the print bed, and consistent results, making it ideal for beginners.

- Low Toxicity: PLA is safer to work with compared to other materials like ABS. It emits a mild, sweet odor during printing, which is generally non-toxic.

- Print Temperature: PLA prints at lower temperatures (around 180°C to 220°C), which makes it compatible with a variety of 3D printers.

- Strength and Rigidity: PLA is a rigid material but is more brittle compared to ABS. It is suitable for decorative and low-stress applications.

- Applications: PLA is commonly used for creating prototypes, 3D printed art, food containers, and in the medical industry for things like biodegradable medical implants.

- Limited Heat Resistance: PLA has low heat resistance, and can deform in high-temperature environments (such as in a car on a hot day), making it unsuitable for high-heat applications.

About ABS Material

Acrylonitrile Butadiene Styrene (ABS) is another widely used thermoplastic polymer known for its durability, toughness, and resistance to impact. ABS is commonly used in 3D printing for applications that require functional and mechanical strength.

Key Characteristics of ABS:

- Strength and Durability: ABS is much stronger than PLA and can withstand mechanical stress and vibrations, making it ideal for creating functional parts.

- Print Temperature: ABS requires higher printing temperatures (220°C to 250°C), meaning that more advanced 3D printers with better temperature control are required.

- Heat Resistance: ABS has superior heat resistance compared to PLA, which allows it to be used in automotive, electronic, and other high-temperature environments.

- Flexibility: ABS is more flexible and less brittle than PLA, which makes it suitable for parts that need to be bent or subjected to mechanical stress without breaking.

- Post-Processing: ABS can be smoothed with acetone vapor, giving it a glossy finish and smoothing out any print lines, which is difficult to achieve with PLA.

- Applications: ABS is used in a variety of applications such as automotive parts, electronic housings, toys, and household products.

PLA vs ABS: Key Differences

PLA is ideal for beginners due to its ease of printing, while ABS offers greater durability and mechanical properties for functional applications.

1. Material Composition:

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable plant-based resources such as cornstarch, tapioca roots, or sugarcane. Its eco-friendly nature makes it popular for environmentally conscious users and educational environments. In contrast, ABS (Acrylonitrile Butadiene Styrene) is a petroleum-based plastic known for its strength and durability. However, its non-renewable composition makes it less favorable from a sustainability perspective.

2. Ease of Printing:

One of the biggest advantages of PLA is its ease of use. It has excellent bed adhesion, minimal warping, and does not require a heated bed—making it a top choice for beginners, educators, and hobbyists. ABS, on the other hand, is more temperamental. It tends to warp and crack if printed in an environment without a heated bed or enclosure, making it more suitable for experienced users or those with enclosed 3D printers.

3. Print Temperature:

PLA prints effectively at relatively low temperatures, typically between 180°C to 220°C. This makes it compatible with a wider range of entry-level 3D printers. ABS requires higher extrusion temperatures of 220°C to 250°C, and the heated bed must be maintained around 90°C to 110°C. Additionally, ABS printing benefits greatly from a controlled, draft-free environment to avoid warping.

4. Strength and Durability:

ABS is favored for mechanical parts due to its superior toughness and impact resistance. It’s capable of withstanding rough use and is commonly used in automotive and industrial applications. PLA, while stiffer and more rigid, is also more brittle. It can snap under stress or drop impact, making it less ideal for functional parts that require resilience.

5. Temperature Resistance:

When it comes to thermal performance, ABS holds a clear advantage. It maintains structural integrity at higher temperatures, making it suitable for objects exposed to sunlight or heat. PLA, however, starts softening at temperatures around 60°C, which means it can deform in warm environments like inside a car on a hot day.

6. Odor and Emissions:

Printing PLA emits a mild, sweet smell similar to cooking sugar due to its natural origin, and it’s generally considered safe for indoor use. ABS, in contrast, releases unpleasant and potentially harmful fumes during printing. Proper ventilation is essential when using ABS, and printing in a well-ventilated area or using an enclosed printer with an air filter is highly recommended.

7. Post-Processing:

ABS shines in post-processing capabilities. It can be easily sanded, drilled, or vapor-smoothed using acetone to achieve a glossy, injection-molded-like finish. This makes it great for prototypes or consumer-facing products. PLA, while easier to paint and glue, doesn’t respond as well to sanding or chemical smoothing and can be more challenging to finish cleanly due to its brittleness.

8. Cost and Availability:

Both PLA and ABS are widely available and relatively affordable, but PLA tends to be slightly cheaper and comes in a broader range of colors and specialty blends (like silk, glow-in-the-dark, or wood-filled). This makes PLA a versatile option for creative and artistic prints, while ABS is preferred where performance matters more than aesthetics.

9. Environmental Impact:

PLA is biodegradable under industrial composting conditions, which aligns well with sustainable practices. However, it’s important to note that it still requires proper disposal to degrade effectively. ABS is not biodegradable and contributes to long-term plastic waste if not recycled properly. If sustainability is a priority, PLA is generally the better choice.

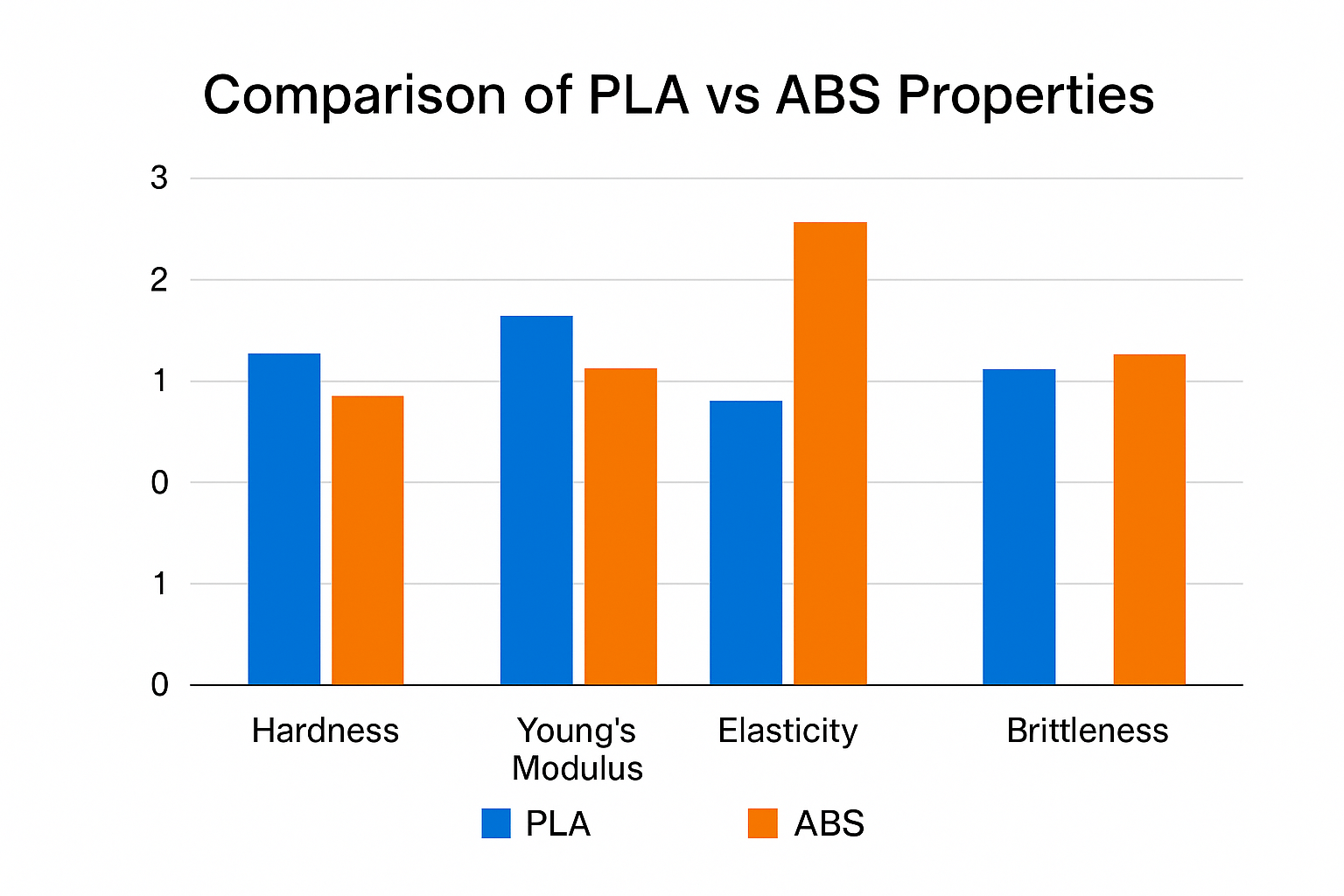

Key Properties Comparison

| Property | PLA | ABS |

|---|---|---|

| Hardness (Shore D) | 55-60 | 70-80 |

| Young’s Modulus (GPa) | 2.5-3.5 | 2.1-2.7 |

| Elasticity (MPa) | 1500-2500 | 2000-3000 |

| Flexural Strength (MPa) | 60-80 | 50-70 |

| Impact Strength (Izod, J/m) | 5-10 | 10-20 |

| Brittleness | More brittle | Less brittle, more impact resistant |

| Plasticity | Low plasticity | Higher plasticity, more flexible |

| Heat Resistance (°C) | 60°C (Softens) | 100°C (Good heat resistance) |

| Temperature Resistance | Low heat resistance, softens at lower temperatures | Better heat resistance, suitable for higher-temperature environments |

| Environmental Impact | Biodegradable, made from renewable sources | Petroleum-based, non-biodegradable |

In this technical comparison, we’ve highlighted the key differences between PLA and ABS materials, focusing on aspects like hardness, elasticity, and impact resistance. Generally, ABS excels in strength, flexibility, and heat resistance, making it well-suited for mechanical and industrial applications. In contrast, PLA is more environmentally friendly, easier to print, and perfect for prototypes or decorative items, although it lacks the same mechanical strength and temperature tolerance.

Summary

To summarize, PLA is user-friendly, biodegradable, and great for aesthetic or display parts, while ABS is better for functional, load-bearing, or high-temperature applications. Choosing between them depends on your project’s specific functional and environmental needs.

Looking to bring your designs to life? We offer affordable 3D printing services tailored to your requirements. Use our instant quotation tool to upload your STL file and get a price immediately—fast, reliable, and hassle-free!

Thank you for reading! You now have a clear understanding of the differences between PLA and ABS. Stay tuned for our next blog, where we’ll dive into the world of SLM 3D Printing.