How it is Revolutionizing Engineering and Design Industries

Engineering and design have undergone a revolution because of computer-aided design (CAD), which has significantly improved productivity, efficiency, and accuracy. In order to give a thorough understanding of CAD, this blog will examine its background, essential elements, advantages, and applications. We thoroughly investigate the numerous CAD software programs on the market and look at how CAD affects sectors including architecture, manufacturing, automotive, aerospace, and entertainment. We may grasp CAD’s impact on modern design practices and innovation by realizing its transformative capacity.

1. What is CAD?

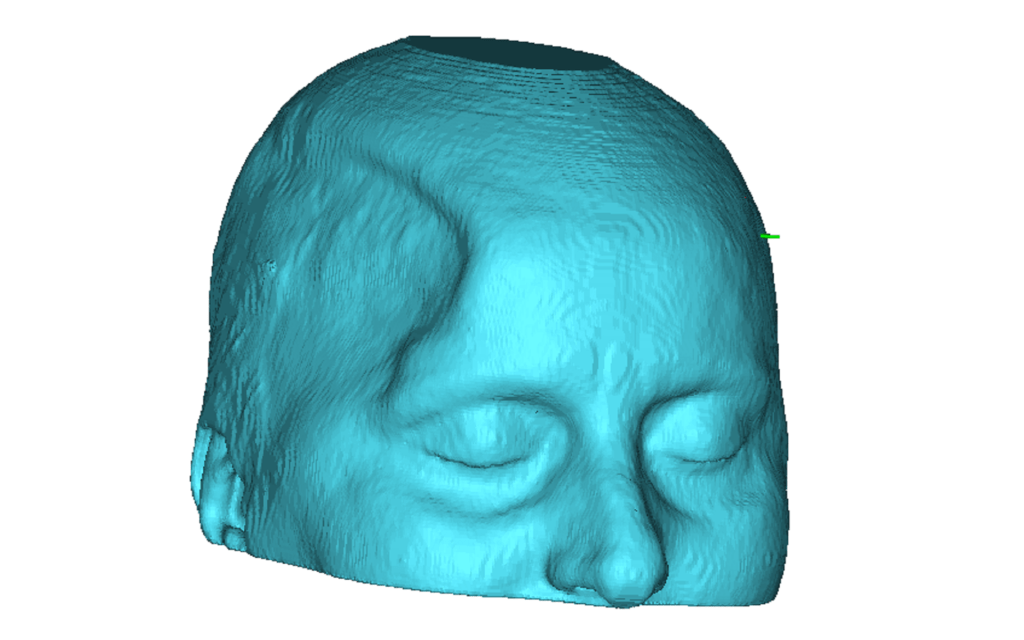

Fig. 1:- Creating a design on CAD software

CAD is referred to as Computer-Aided Design, in which computer systems are used to assist in the creation, modification, analysis, or optimization of a design, for this various computer designing software were used for the designing processes. Nowadays they are frequently used to create digital 2D & 3D designs by almost every designer and engineer.

Using computer software and systems, computer-aided design (CAD) creates, modifies, analyzes, and optimizes designs for systems or things. It allows designers, engineers, architects, etc. to create virtual representations of their designs or of their thoughts, replacing or enhancing manual drawing techniques.

CAD software offers capabilities for generating technical drawings, running simulations, and recording design data as well as for building geometric models. It makes it easier to collaborate between designers, create intricate 2D and 3D models, and assess the effectiveness of designs. The fundamental idea behind CAD is to give the design a precise digital representation that can be used for visualization, simulation, prototyping, and analysis. Different industries’ design processes have been revolutionized by CAD, which has increased productivity, design quality, and innovation.

2. Who uses CAD?

Computer-aided designs were used by various design professionals, mainly used by the architect, mechanical engineers, and civil engineers, to transfer their thinking into the design. The uses are not only restricted only to these fields but there are various field people involved in this process.

Here are some more examples-

- Graphic designers

- Drafters

- Interior and exterior designers

- Fashion designers

- Games designers

- Industry designers

- Product designers

- manufacturers

3. Benefits of using CAD

CAD is basically used before making the actual product or before giving any product to manufacturing or production. It provides a platform for any designer to make their product virtually in 2D and 3D format as shown in Fig 1, the designer also checks all the features on CAD software, they even check if the product fails or where the problem can occur after making the product fig. 2 (b).

a)

b)

Fig. 2:- a) Making BILL of Material [BOM] of a completely assembled product (spiceworks), b) analysis of the design before giving it to the manufacturing or production department (3Dcadworld).

CAD software offers a platform for designers where they can see the product 360 degrees after designing, and get a better understanding of the design, and also by this a designer can better explain their concept to others.

Fig. 3:- Explaining the design to another person by pen and paper, it is very tough to explain to another person what you actually think and how it looks, and it’s very time-consuming too.

Fig. 4:- CAD makes it easier for designers and manufacturers to understand each other and to better explain the design to each other. CAD allows you to showcase the design in 360 degrees and to explode the design to show the complete assembly of the product in one frame.

It also saves the time of the designers, because now the designer does not have to manually take a scale and mark all the dimensions and make the design on the paper sheet, where there is no scope for error because if any error occurred the designers have to again design the whole design on a new paper sheet from zero.

Fig. 5:- Old way of making the design on paper sheets.

Whereas on the other hand, a variety of advantages are offered by computer-aided design, CAD has completely changed the process of how designing is done in any industry. By automating manual activities, allowing quick revisions, and speeding up design iterations, CAD increases efficiency and production. Errors are minimized by ensuring accuracy and precision in measurements and dimensions. CAD encourages design exploration and iteration, promoting creativity and different design approaches. CAD facilitates effective communication and cooperation, enabling real-time feedback and efficient operations. By spotting and fixing problems before production, CAD saves money and time and helps with 3D printing and rapid prototyping. Realistic representations and visualization help people comprehend design ideas and reach wise conclusions. Design analysis and simulation for assessing performance and behavior are made possible by CAD.

4. CAD Software/Tools

CAD software tools are designed to provide a comprehensive set of features and functionalities for creating, modifying, analyzing, and documenting designs. There are numerous CAD software options available, each with its own strengths and specialized applications. the creation, modification, analysis, or optimization of a design, for this various computer designing software were used for the designing processes. Nowadays they are frequently used to create digital 2D & 3D designs

Here are some examples of rapidly used CAD software/tools by the industry exports-

- Dassault CATIA

- Dassault Solidworks

- Siemens NX

- CREO

- AutoCAD

- Fusion 360

These are only a few examples that were variously used by the industries or industry person, there are many more software available for designing.

5. Advantages & Disadvantages of CAD

Advantages

- Increased Efficiency and Productivity: CAD automates many manual design tasks, reducing the time required to create and modify designs. Designers can work more efficiently, allowing them to focus on creative aspects rather than repetitive tasks. This leads to faster design iterations and shorter project timelines.

- Enhanced Design Accuracy: CAD software provides precise tools for creating and editing designs. Designers can ensure accurate measurements, dimensions, and tolerances, reducing the risk of human error and resulting in higher-quality designs.

- Design Visualization: CAD allows designers to create realistic 3D visualizations of their designs. This enables stakeholders to better understand the final product’s appearance and functionality, leading to more informed decision-making and better communication among team members.

- Easy Design Modifications: CAD allows for quick and seamless design changes. If alterations are required, designers can easily modify the digital model, and the changes propagate through the entire design, reducing the need for time-consuming manual revisions.

- Design Simulation and Analysis: Many CAD tools include simulation and analysis capabilities. Designers can test how the product will perform under various conditions, such as stress, heat, fluid dynamics, or motion. This helps identify potential issues and optimize designs before physical prototyping or manufacturing.

- Collaboration and Data Sharing: CAD facilitates collaboration among team members, even across different locations. Designs can be shared electronically, allowing real-time feedback and reducing the need for physical prototypes and meetings.

- Design Documentation and Manufacturing Preparation: CAD software generates accurate technical drawings, bills of materials (BOMs), and assembly instructions. These documents serve as valuable instructions for manufacturers, reducing errors during production.

- Cost Reduction: By catching design flaws early in the process through virtual simulations, CAD helps avoid costly modifications and rework during physical prototyping or production.

- Innovation and Design Exploration: CAD enables designers to experiment with various design iterations and explore innovative solutions without the constraints of physical prototyping. This fosters creativity and supports the development of cutting-edge products.

- Environmental Benefits: CAD reduces the need for physical prototypes and excessive material waste, promoting a more sustainable design process.

Disadvantages

- Initial Cost and Learning Curve: CAD software can be expensive, especially for high-end packages with advanced features. Additionally, learning to use CAD software effectively may require specialized training, which can further add to the initial investment.

- Hardware Requirements: CAD software demands powerful hardware to run smoothly, particularly for complex 3D models and simulations. Upgrading computer systems to meet these requirements can be costly.

- Software Updates and Compatibility: Frequent software updates and new versions can cause compatibility problems with older files, leading to data migration and conversion challenges.

- Data Security and Intellectual Property: CAD files may contain sensitive intellectual property, and ensuring data security is critical. Unauthorized access or breaches of security can lead to potential intellectual property theft or unauthorized use of designs.

- Dependency on Computer Systems: Relying on CAD software means that if computer systems crash or malfunction, designers might be unable to work until the issues are resolved, leading to potential downtime.

- File Format Compatibility: Different CAD software packages may have varying file formats, leading to potential difficulties in sharing and collaborating across platforms.

Career

Fig. 6- In this figure, it shows the ladder of career for a mechanical design engineer, and how one can achieve success in his/her career as a design engineer in industry.

- Design and Modeling: CAD allows you to create detailed 3D models of mechanical components, products, or systems. This capability enables you to visualize and iterate designs efficiently, ensuring they meet performance requirements and adhere to engineering standards.

- Prototyping and Testing: CAD software enables you to simulate and analyze the behavior of mechanical designs under various conditions. This simulation helps you identify potential issues, optimize designs, and make informed decisions early in the design process, reducing the need for costly physical prototypes.

- Documentation and Technical Drawings: CAD allows you to generate accurate technical drawings and documentation required for manufacturing. These drawings provide precise instructions to manufacturers, reducing errors and ensuring the final product aligns with the design intent.

- Innovation and Product Development: CAD empowers you to explore innovative design concepts and solutions. By experimenting with different design iterations, you can push the boundaries of creativity and develop cutting-edge products.

- Integration with Manufacturing Processes: CAD can be integrated with computer-aided manufacturing (CAM) and computer-aided engineering (CAE) software, allowing you to optimize manufacturing processes, create tool paths, and perform simulations to validate manufacturability.

- Industry-Specific CAD Tools: Some CAD software is specifically tailored for mechanical engineering applications. These specialized tools offer advanced features for modeling complex mechanical components, sheet metal design, and surface modeling, among others.

- Project Management: CAD software often includes project management tools that allow you to organize and track design projects, making it easier to manage timelines and deadlines effectively.

Conclusion

In conclusion, design procedures across sectors have been transformed by computer-aided design (CAD), which has become a transformative force. The ability to develop, alter, and visualize complicated models with unparalleled efficiency and accuracy has been made possible by this potent digital design tool for designers, engineers, and architects. Significant time and money savings, faster processes, and improved team collaboration have all been made possible by the benefits of CAD, including increased productivity, improved accuracy, and design exploration capabilities. CAD is positioned to play an increasingly more crucial role in determining the future of design and innovation as technology develops, driving various industries toward new heights of innovation and productivity. Unlocking CAD’s full potential, advancing technology, and pushing the limits of what is feasible in the design and engineering fields all depend on embracing it as a fundamental component of contemporary design practices.

Thank you, for being with us till here, now I think you understand what is CAD and how it Revolutionizes Engineering and Design Industries.

We here at Shokitech provide best-in-class 3D CAD Design Services, we have a team of very elite and innovative designers with us, who can convert your imagination into 3D reality.

So please be in touch with us if you need anything from us, our team will be honored to work with you,

Do you ever listen the term 3D printing, and wonder how it actually works, and how you can also learn it, and print your own imagination into a real 3D part?

Be with us, in our next blogs, we will learn more about this world in deep.

So, till then keep being awesome and keep learning, We will meet again in our next blog.