Orthopedic Plaster Cast

In the general population, bone fractures can happen as a result of mechanical trauma or bone disorders. The majority of fracture patients have been treated with plaster or fiberglass casts. As they stabilize the mobility of anatomical components of the body, particularly the bones, orthopedic casts are frequently used to heal broken bones. A soft inner cotton layer and a hard outside plaster or fiberglass layer are used in the current crude casting procedures.

Orthopedic Plaster Cast (Source – Fracture treatment plaster, Dr. Ashwini Gaurav)

Traditionally, body-based contracting models are used to create orthopedic casts or orthoses.

Making of Orthopedic plaster cast (Source – Alamy)

Problems in the traditional orthopedic cast

In traditional techniques, there are a lot of issues or problems that were faced by the patients –

- The limb is unreachable during treatment, causing the skin under the cast to become dry and uncomfortable.

- Since the limb is covered by the cast, the area under the plaster cannot be cleaned and can sometimes result in an infection or rash.

- The plaster casts can be of considerable weight, which may result in restricted or uncomfortable movement.

- We have to prevent the plaster from being cast with the water, it can’t get wet, as this can cause the plaster to crack or disintegrate.

- It also takes several days to fully harden, so we need to limit our activities.

- Plaster casts tend to be heavier as well, so they can pose a challenge to small children.

- Trouble in taking it off, it has to be removed with scissors by a doctor, & the procedure is painful also.

Complications of Orthopedic plaster cast (Source – Goyal Hospital)

Substitute for traditional method

Substitution for the traditional orthopedic plaster cast, is a 3D printed orthopedic plaster cast. The reason for using 3D printing in an orthopedic plaster cast is that it is the best option for the replacement of traditional orthopedic plaster.

3D printing of the orthopedic cast (Source – Additive report)

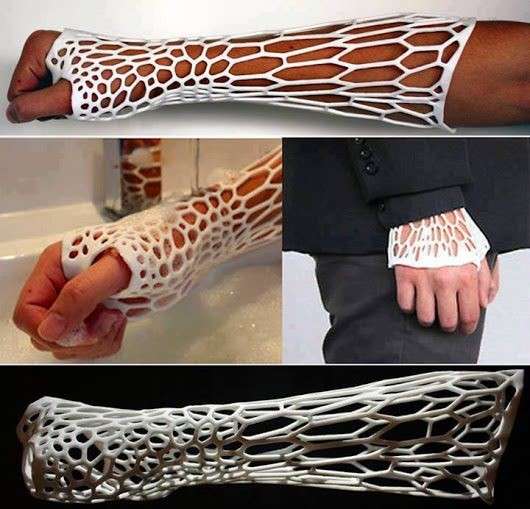

The orthotics business is undergoing a change because of 3-D printing technology. Patients with shattered bones no longer have to endure itchy, bulky, and painful plaster casts thanks to 3-D printed casts.

3D Orthopedic Plaster (Source – prnewswire)

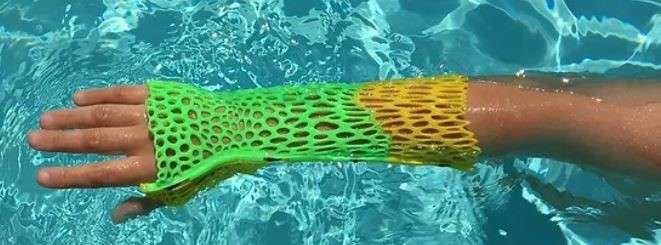

For common fractures in the hands, fingers, arms, and legs, 3-D printed splits are employed. They raise the patient’s standard of living. Splints that are 3-D printed are modified to fit the anatomy and pathophysiology of the patient.

3D Orthopedic Plaster in Water Pool (Source – Play Cast)

Because the 3-D printed splints are waterproof and more attractive in appearance, patients can wear them while on vacation at the beach or in swimming pools.

3D Orthopedic Cast (Source – 3D2GO)

You can also wear it in any function because of its lightweight shape & size, it is not bulky and heavy in weight, and it also looks very attractive in aesthetic look. And not only you can wear it at parties, but also you can play sports wearing it. Isn’t it awesome?

An athlete playing wearing 3D orthopedic plaster cast (Source – Additive Report)

There are a lot of things you can do by wearing these 3D-printed orthopedic casts, which you can’t imagine by wearing a traditional orthopedic plaster cast. Whether you are a professional athlete, a party guy, or you love swimming. You can do whatever you want to do. Splints that are 3-D printed are constructed from recyclable or biodegradable materials like PLA (polylactic acid). We can take advantage of three things: Environmentally friendly and incredibly simple to print, polylactic acid (PLA) is a substance generated from plants, such as maize. We also employ thermoplastic polyurethane (TPU), one of the most widely used materials for splints since it is adaptable, lightweight, recyclable, and has great mechanical and chemical resistance. Additionally, we employ thermoplastic elastomeric polyurethane (TPE), a more durable material than conventional flexible filaments and resistant to chemicals like acids and solvents.

Xkelet 3D printed plaster casts Source – mddionline

3D-printed casts from Cast Print Source – Forbes

Market survey

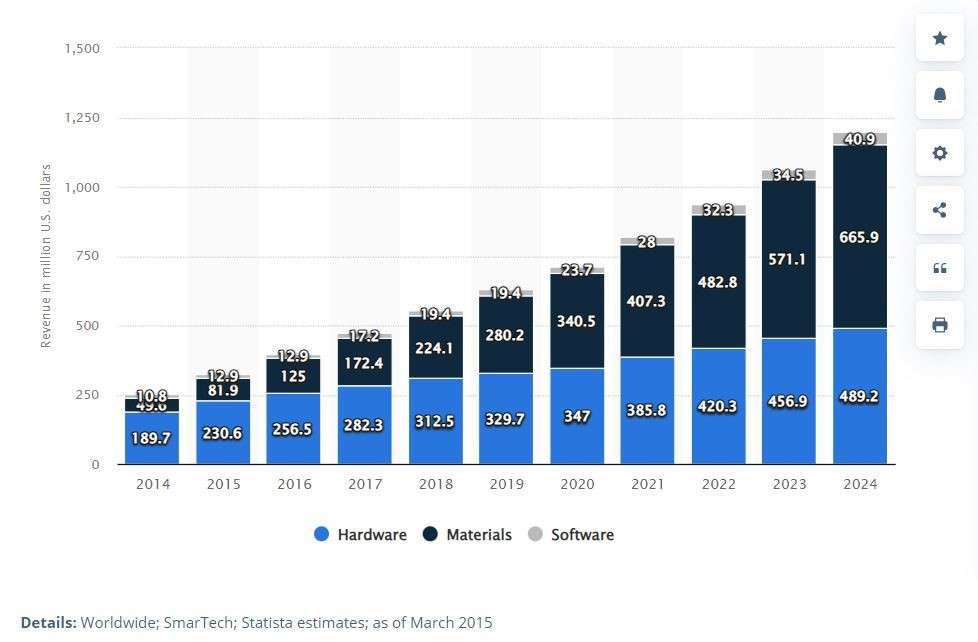

This statistic provides a projection for the global market for medical 3D printing from 2014 to 2024, broken down by category and expressed in million US dollars. The medical 3D printing industry is anticipated to reach a value of around 1.2 billion dollars by 2024, with materials making up the majority of this sum.

Medical 3D printing market value worldwide from 2014 to 2024, by category (in million U.S. dollars)

Methodology

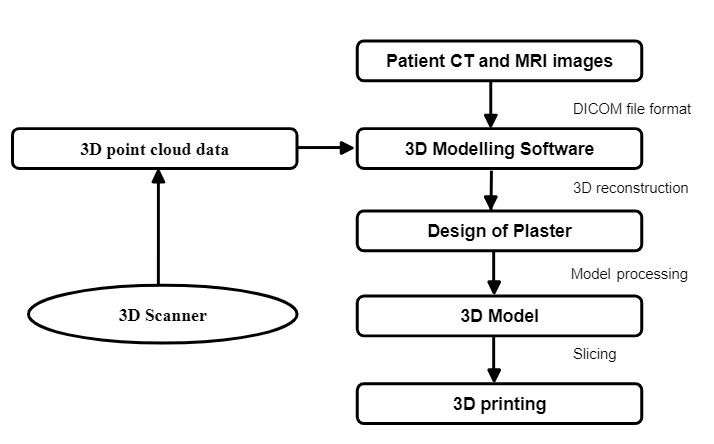

3D Printing and Manufacturing Framework

Challenges of 3D Printing Orthopedic Cast

- Although they provide a variety of benefits, there may also be some disadvantages. One of the biggest dangers of 3D-printed casts is that if the limb is swollen during the first scan, the cast could not fit properly. When the swelling takes place, the afflicted region may grow in size, resulting in your print not fitting properly. It will then be necessary to repeat the process, which may be both time- and money-consuming.

- Another drawback is that patients who require urgent care cannot use 3D-printed casts. This is due to the fact that creating and processing the print might take some time, which may not be feasible for patients with major fractures. Additionally, patients who need to manipulate their bones back into position should avoid wearing 3D-printed casts.

- Traditional casts are less expensive than 3D-printed ones, but the expense might not be covered by insurance. Before selecting a 3D-printed cast for your injury, it’s crucial to be informed of any potential drawbacks even though this technology is continually developing.

Some extra applications other than humans

These 3D printing orthopedic plaster casts are not only limited to human use, but it is also very helpful in the treatment of different animals. Because it is not possible for the traditional method of orthopedic plaster cast to treat animals with broken bones, but now because of 3D orthopedic plaster cast it is now possible to treat animals with broken bones.

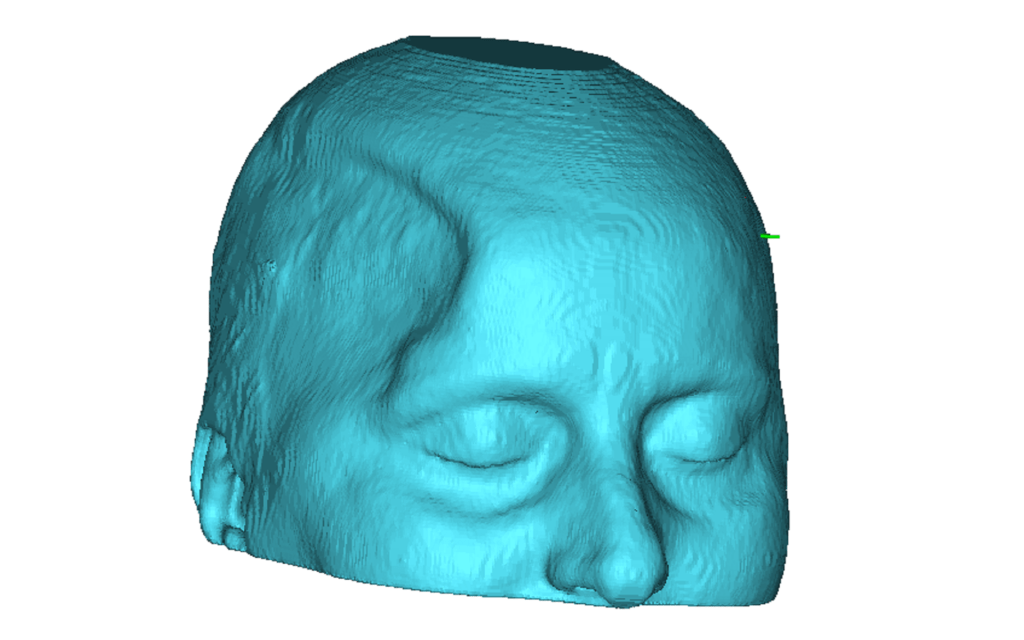

A dog having a skull fracture has been treated with the 3D printing plaster technique.

A baby deer having some fractures in his skull has been treated with a 3D plaster cast.